Top 10 UPVC Profile Manufacturers in India

Top 10 UPVC Profile Manufacturers & Suppliers in India: A Complete Buyer’s Guide to Quality, Performance & Trust:-

Call: 89855 87272

Top 10 UPVC Profile Manufacturers in India — this guide dives deep into what the phrase really means today, why these manufacturers matter for builders, architects and homeowners, and how the market is evolving. In a country that’s rapidly urbanising and doubling down on energy-efficient housing, uPVC profiles have become more than a product category: they’re a performance and longevity decision that affects comfort, maintenance costs, thermal comfort, and resale value. Recent market studies show strong, sustained growth for the uPVC doors and windows market in India, driven by large housing pipelines, energy-efficiency demand, and a preference for low-maintenance materials.

Top 10 UPVC Profile Suppliers in India

Top 10 UPVC Profile Suppliers in India — when people say “top suppliers,” they mean companies that consistently deliver a blend of quality material, certified processes, wide distribution, and reliable post-sales support. A “top supplier” is measured not only by production volumes but also by adherence to national standards, supply-chain transparency, presence of technical support, warranty policies, and the ability to service projects across climate zones. Whether you’re a developer ordering bulk runs or a homeowner selecting a profile system for a retrofit, these supplier attributes are what separate merely available products from genuinely dependable ones.

Why uPVC profiles?

The demand for uPVC in India is solidifying into a mainstream choice for fenestration (windows & doors) because it delivers a rare combination: thermal performance, low maintenance, long life, and design flexibility. Market research projects robust compound annual growth for uPVC doors & windows as urban construction and retrofit projects increase. That’s why understanding the makeup of “top 10” manufacturers and suppliers — their capabilities, quality checks, manufacturing methods, and selection criteria — is essential if you want the finished window/door to perform as promised.

What makes a uPVC profile “best-in-class”?

To evaluate or rank the “top 10 UPVC Profile Manufacturers & Suppliers,” professionals use a consistent checklist. This section explains each item so you can judge vendors by substance, not marketing.

1.Raw material quality & formulation control — Premium uPVC profiles start with high-quality resin and carefully balanced stabilisers, UV absorbers, and impact modifiers. The compound mix determines colorfastness, brittleness, and long-term thermal stability.

2.Extrusion precision & tooling — An advanced extrusion line with well-designed dies and precise pullers ensures dimensional accuracy and minimal warpage. Good tooling reduces scrap and ensures consistent wall thickness — crucial for strength and sealing.

3.Thermal & structural testing — Top manufacturers run tests for heat ageing, elongation, impact resistance and thermal conductivity. Conformance to national standards (see India’s IS 17953) demonstrates third-party validation.

4.Design systems & multi-chamber profiles — The geometry of chambers in a profile affects thermal break and reinforcement placement. Best systems are engineered for both glazing options and hardware integration.

5.Color stability & coatings — Profiles exposed to sun must resist yellowing and chalking. Stability packages and quality surface engineering help prolong aesthetics.

6.Supply-chain & logistics strength — A top supplier can deliver consistent lengths and colors, and respond quickly to site changes. Good distribution reduces lead time risk on projects.

7.Technical support & documentation — Engineering drawings, installation guides, and on-site troubleshooting separate market leaders from commodity sellers.

8.Certifications & compliance — Adherence to IS standards, relevant test certificates, and explicit guarantees on mechanical and thermal properties build buyer confidence.

9.Sustainability & recyclability — Leading manufacturers now provide recyclable uPVC formulations and take-back schemes or cradle-to-cradle thinking, which matters for green buildings and certifications.

10.After-sales warranty & spare availability — Profiles that are backed by warranties and steady supply of matching components (gaskets, corner-welds, glazing beads) make long-term maintenance predictable.

A clear view of how uPVC profiles are manufactured?

Understanding the extrusion-based manufacturing process helps you separate performance claims from marketing:

1.Raw compound mixing: Resin, stabilisers, UV filters and modifiers are blended in controlled mixers to create a consistent compound. The exact formulation is proprietary, but quality producers monitor melt-flow index and additive dispersion closely.

2.Extrusion: The compound is heated and forced through a die that forms the cross-sectional profile. The die design, cooling tanks and pullers determine final dimensions and surface finish. Modern plants use automatic thickness and temperature controls to reduce variability.

3.Quality inspection: Profiles undergo dimensional checks, surface inspection and sample testing for flexibility, impact and weathering. Profiles failing tolerance or surface standards are rejected or reworked.

4.Packaging & logistics: Proper packing prevents UV and mechanical damage in transit; documented batch traceability ensures any field issues can be traced back to production parameters.

This technical transparency is why many architects insist on factory visits or third-party test reports before specifying a supplier for major projects.

India’s standards and why they matter:-

IS 17953 (uPVC profiles for windows and doors) provides prescriptive and performance criteria for materials, dimensional tolerances and testing procedures — it’s the reference document for manufacturers and specifiers in India. Following the standard means profiles have undergone a consistent battery of tests and that dimensional tolerances and raw material requirements meet a national benchmark. For buyers this reduces the risk of premature fading, warpage, or poor hardware fit. Supplementary draft guidance from industry bodies like the Indian Vinyl Council reinforce testing methods and material traces for recyclability and safe additives.

Why you should prioritize certified profiles?

Installing non-certified or under-specified uPVC profiles can produce expensive failures: warped sashes, leaking joints, hardware failure due to improper reinforcement channels, or premature discoloration. In contrast, profiles from top-tier manufacturers and suppliers commonly include documented test reports, traceable batch numbers, and fitter training — all of which reduce long-term cost and headaches. Market reports show that as projects move toward energy codes and sustainability certifications, the premium for verified uPVC systems is justified by lower life-cycle cost.

What architects and builders should inspect during selection?

If you’re specifying or buying, insist on the following before signing a bulk order:

Latest test certificates and batch traceability for the supplied profiles.

Dimensional verification and sample cut-sections to check wall thickness and chamber geometry.

Demonstration of extruder capacity, tooling maintenance and sample production dates.

Clear warranty on mechanical properties, color retention and service life, ideally with service-level commitments.

These checks are quick but they catch the majority of fit-and-finish risks that lead to callbacks.

The supply side: what “Top 10 UPVC Profile Manufacturers & Suppliers” typically offer?

Rather than naming companies, here’s what the top-10 tier generally brings to the table — the traits that convert a supplier into a reliable partner:

1.Multiple profile systems: A range of systems for sliding, casement, tilt-and-turn, and commercial curtain-wall type fenestrations.

2.Reinforcement designs: Standardised steel/aluminium reinforcement channels and correct screw bosses to work with hardware without cracking.

3.Glazing flexibility: Profiles engineered for single, double or triple glazing — with dedicated beads and gasket systems to ensure water-tightness.

4.Custom extrusions: Ability to supply custom colors, co-extruded surface finishes (in some cases), and modified chamber geometries.

5.Training & support: On-site fitter training, troubleshooting and technical documentation for fabricators and installers.

6.Regional distribution: Multiple warehouses or logistics partners to reduce lead time on long projects.

7.Warranty & clarity: Clear limits of warranty — what’s covered, what voids the warranty (e.g., misuse, thermal overloading), and spare parts availability.

Market drivers shaping the top-10 list:-

Several macro and micro factors elevate certain manufacturers and suppliers into the “top-10” conversation:

1.Energy codes & green building adoption: Greater attention to thermal performance pushes buyers to specify engineered multi-chamber profiles that support double-glazing.

2.Urban housing boom & retrofits: Large-scale housing projects and retrofit demand from apartments drive volume orders, favouring suppliers with robust logistics.

3.Climate resilience: Coastal and high-UV regions require special formulations and reinforcements — manufacturers that invest in climate-specific R&D score higher.

4.Sustainability: Recyclability and responsible compound sourcing are increasingly important for institutional buyers and developers.

Purchasing guidance: how to choose from the top-10 tier:-

1.Define performance needs — thermal, acoustic, security, and design aesthetics.

2.Request test documentation — IS 17953 compliance and recent lab reports.

3.Inspect sample profiles — measure wall thickness, chamber geometry and glazing rails.

4.Check reinforcement options — confirm compatibility of reinforcement sections with hardware.

5.Ask about lead times & logistics — especially for large projects where delays are costly.

6.Evaluate warranty & spare part policy — understand what voids warranties and how replacement components are handled.

Cost versus value: understanding price signals:-

Lower-priced profiles may save upfront cost, but the hidden costs can be significant: higher fabrication scrap rates, increased callbacks, faster color degradation, or poorer thermal performance that increases HVAC bills. The “top-10” players tend to price for predictable performance and lower life-cycle cost — not just the cheapest per-metre price. Use whole-life costing (purchase + installation + 10–15 years of operation) rather than a simple per-metre comparison.

Installation & fabrication — why supplier expertise matters:-

Quality profiles are necessary but not sufficient. The final performance heavily relies on accurate fabrication, corner welding, gasket choice, proper hardware, and correct sealing at site. Top suppliers invest in training fabricators and providing installation manuals and site supervision for critical milestones — that support is part of the “top-10” value proposition.

Future trends that will redefine the top 10 list

Hybrid systems (uPVC with aluminium cladding for slim aesthetics) and co-extruded finishes.

Improved recyclability and certified take-back programs integrated into procurement for large projects.

Smart fenestration integration — pre-designed profiles that accommodate sensors or shading attachments.

Localized R&D focused on extreme-weather formulations that suit India’s varied climate zones.

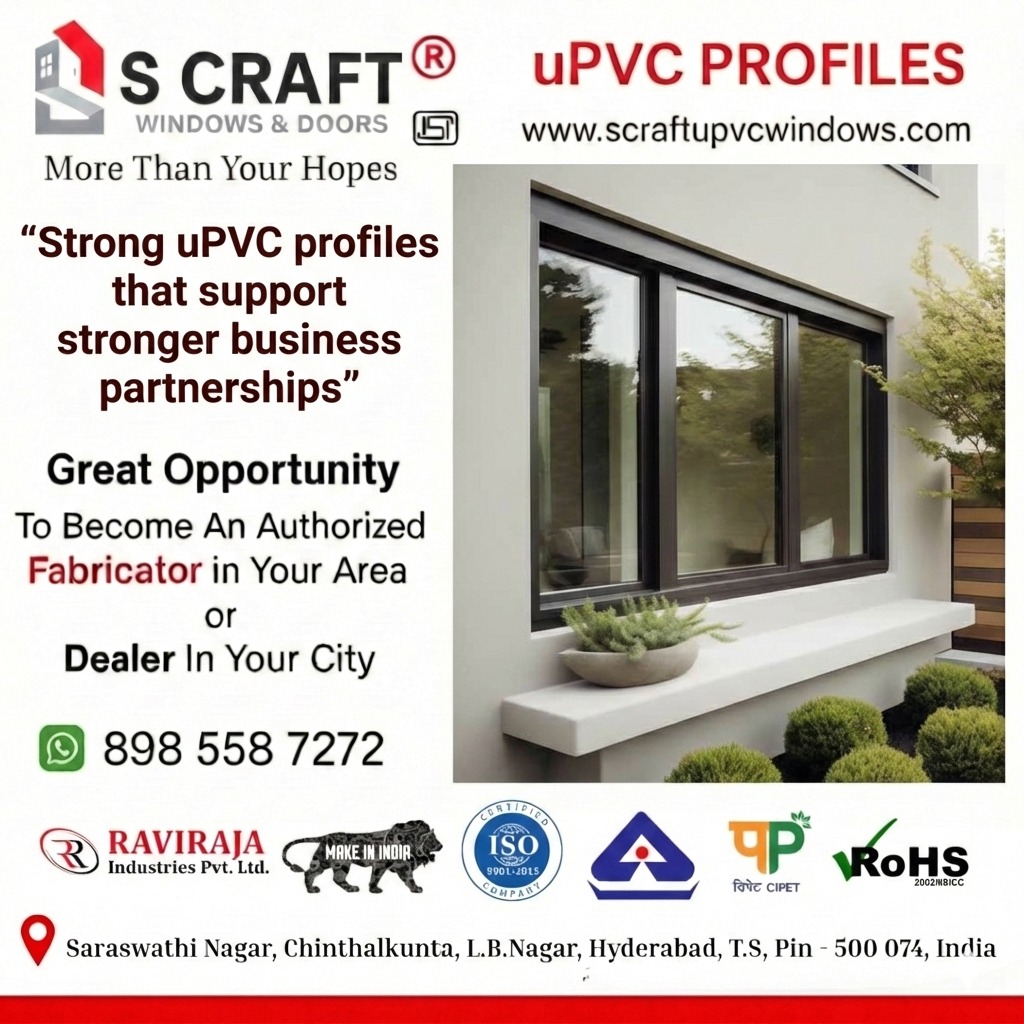

A focused profile: S Craft uPVC Profiles: —

S Craft uPVC Profiles plays a noteworthy role in the context of Top 10 UPVC Profile Manufacturers & Suppliers because it combines manufacturing know-how with service-oriented supply operations that many buyers expect from a top-tier partner. In markets where product reliability is essential,S Craft uPVC Profiles stands out by aligning several crucial capabilities that buyers look for in the upper echelon of suppliers: precise extrusion tolerances, transparent batch traceability, and a documented approach to testing and weathering of profile materials. Their systems are engineered to support varied glazing options — from single-pane retrofit to high-performance double-glazed units — which makes them versatile for residential, commercial and hospitality projects.

A major element of distinction for S Craft uPVC Profiles is the emphasis on training and hands-on technical documentation for installers. The company provides comprehensive fabrication manuals, step-by-step corner-welding best practices, and detailed hardware integration guides — resources that reduce installation errors and warranty claims. These practical resources are especially valuable on large projects where multiple fitters work in different regions, because consistent application of fabrication standards is what preserves the profiles’ designed thermal and water-tight performance.

On the product front, S Craft uPVC Profiles invests in controlled compound formulation and manufacturing discipline. Their extrusion lines are tuned for dimensional accuracy and consistent wall thickness, ensuring that reinforcement channels accept standard steel/aluminium inserts without compromising screw retention or creating stress points. The packaging and logistics approach is designed to minimise UV exposure and mechanical damage during transport; batch numbers and production dates are clearly marked to enable traceability and faster resolution if any field issue appears.

Another strength that places this manufacturer-supplier in the top tier is its responsiveness to project timelines. By offering regional delivery planning, faster replenishment of spare parts, and clear warranty terms, S Craft uPVC Profiles reduces the risk of project delays and punch-list headaches. They also demonstrate awareness of sustainability: materials selection and process optimization emphasize long product life and the potential for recycling at end-of-life — a consideration that increasingly matters to developers seeking green building compliance.

How to brief a supplier when you want a “top-10-grade” delivery?

When you brief any manufacturer/supplier that you expect to perform like the top ten, include:

- Project scope with expected glazing U-values and acoustic goals.

- Expected life-cycle (design life) and warranty expectations.

- Climatic zone and exposure (coastal, high UV, heavy rainfall).

- Delivery schedule with milestones and penalties for missed dates (if large project).

- Request for sample profile sections, certificates and an on-site trial window or mock-up.

l

Choosing wisely for long-term value:-

When discussions revolve around Top 10 UPVC Profile Manufacturers in India, it goes far beyond a simple list of names — it reflects manufacturers who master material formulation, precision extrusion, strict quality checks, and dependable supply systems. Similarly, Top 10 UPVC Profile Suppliers in India are recognised for delivering consistent performance, strong technical backing, and hassle-free logistics that support projects from start to finish. The most reliable players prioritise long-term durability, stable performance, and reduced maintenance costs rather than short-term pricing advantages. By applying a structured evaluation approach, insisting on verified test reports, physically examining profile quality, and valuing service support and documentation, buyers can confidently transform supplier claims into real-world results. As India’s uPVC industry continues to evolve, these factors will clearly separate quick purchases from truly future-ready solutions designed to perform for decades.

Finally, S Craft uPVC Profiles’ combination of product clarity, installer support, and supply-chain discipline illustrates why professional specifiers and building owners may place them among Top 10 UPVC Profile Manufacturers & Suppliers when assessing long-term value, not simply sticker price. Their integrated approach — production discipline, technical documentation, and logistic reliability — addresses the full stack of concerns that matter to architects, project managers and homeowners, making them a pragmatic choice for demanding projects.

FAQs:-

Q: Do uPVC profiles need regular painting?

A: No. Properly formulated uPVC with UV stabilisers retains colour and requires minimal maintenance — occasional cleaning is usually sufficient.

Q: Are uPVC windows energy efficient?

A: Yes — multi-chamber designs and the ability to accept double-glazing make uPVC systems among the most thermally efficient fenestration options.

Q: How long do uPVC profiles last?

A: When made from quality compound and properly installed, profiles can last several decades with little performance loss. Certification and warranty give a reliable longevity estimate.